Nanocellulose Market Size to Worth USD 6.44 Billion by 2035

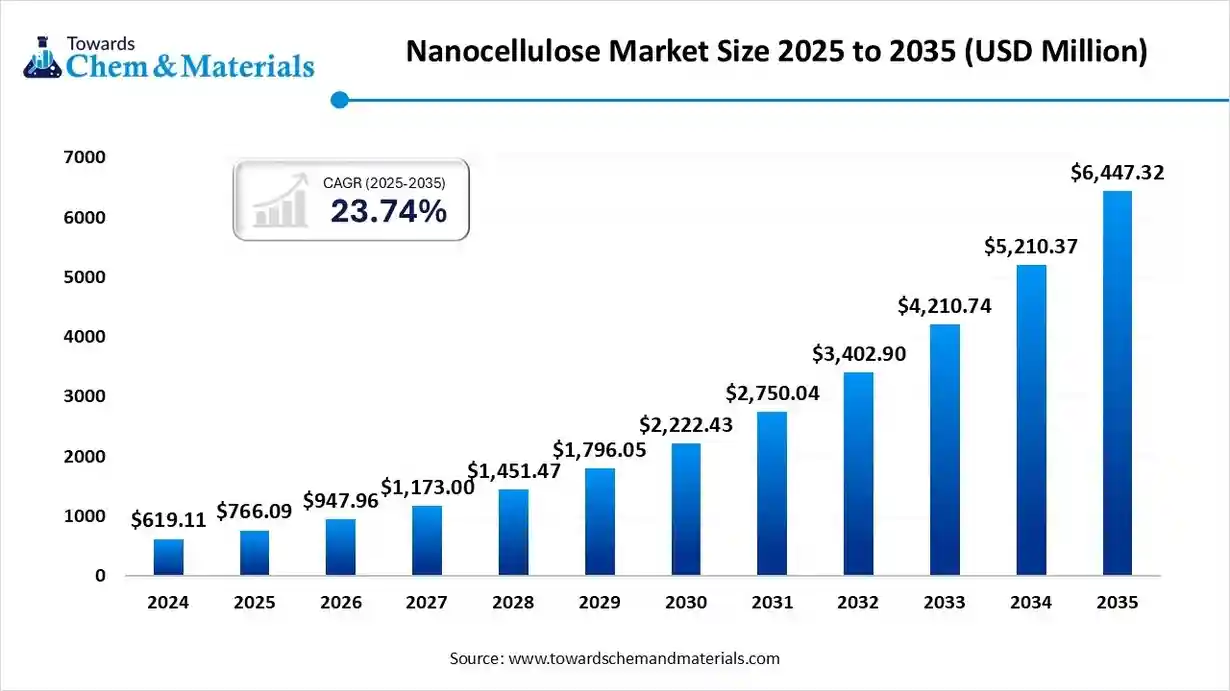

According to Towards Chemical and Materials Consulting, the global nanocellulose market size is calculated at USD 766.09 million in 2025 and is expected to be worth around USD 6,447.32 million by 2035, growing at a compound annual growth rate (CAGR) of 23.74% over the forecast period 2025 to 2035.

Ottawa, Nov. 26, 2025 (GLOBE NEWSWIRE) -- The global nanocellulose market size was valued at USD 766.09 million in 2025. The market is projected to grow from USD 947.96 million in 2026 to USD 6,447.32 million by 2035 at a CAGR of 23.74% during the forecast period. North America dominated the Nanocellulose market with a market share of 45.19% in 2025. Growing demand for sustainable, high-performance materials is driving the nanocellulose market, as industries seek biodegradable and lightweight alternatives to plastics and synthetic additives. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5997

What is Nanocellulose?

The nanocellulose market is growing rapidly as industries shift toward renewable, biodegradable, and high-performance materials. Nanocellulose, derived mainly from wood pulp and agricultural waste, offers exceptional strength, low weight, and a minimal environmental footprint. Its use is expanding across packaging, automotive, electronics, biomedical, and construction sectors due to its versatility and barrier properties. Increasing regulatory pressure to reduce plastic waste is further accelerating adoption, especially in sustainable packaging solutions.

Rising R&D investments and pilot-scale production advancements are helping overcome cost and scalability challenges. Overall, the market is transitioning from early development to broader commercial deployment, supported by strong sustainability-driven demand.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Nanocellulose Market Report Highlights

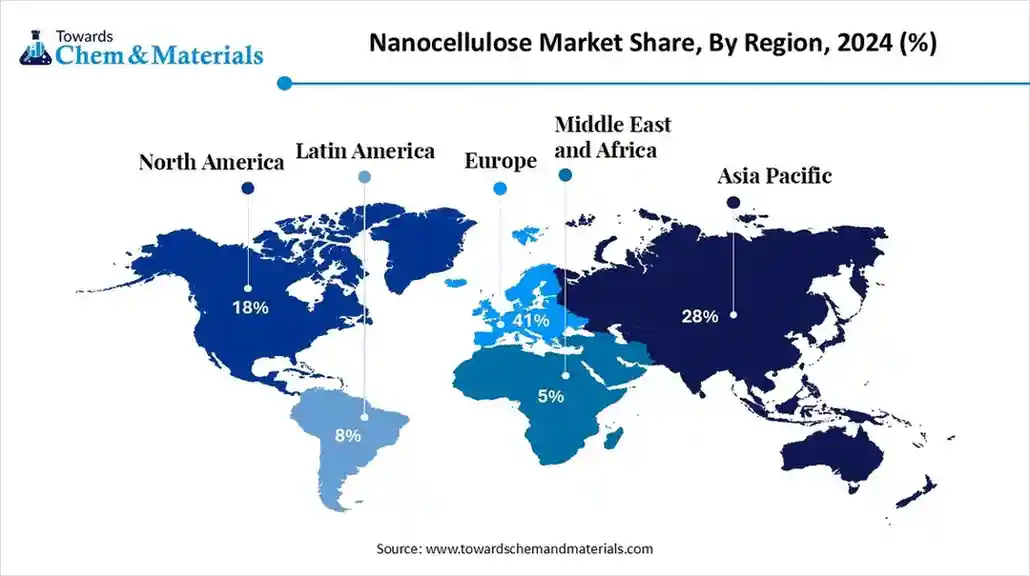

- By region, Europe held a 41% share of the market in 2024.

- By region, Asia Pacific is growing at the fastest CAGR in the market during the forecast period.

- By product type, the cellulose nanofibrils segment held a 46% share in the market in 2024.

- By raw material source, the wood-based pulp segment held a 52% share in the market in 2024.

- By processing technology, the mechanical fibrillation segment held a 48% share in the market in 2024.

- By end-use industry, the packaging segment held a 38% share in the nanocellulose market in 2024.

- By form, the wet form segment held a 61% share in the market in 2024.

Nanocellulose Market of Properties

Nanocellulose is a pseudo-plastic and possesses the property of specific kinds of fluids or gels that are generally thick in normal conditions. The lateral dimensions of nanocellulose range from 5 to 20 nm, and the longitudinal dimension ranges from a few 10's of nanometers to several microns.

The key properties of nanocellulose are listed below:

• Lightweight.

• Stiffer than Kevlar®.

• Electrically conductive.

• Non-toxic.

• Low-density.

• The crystalline form is transparent, and gas impermeable.

• It can be produced in large quantities in a cost-effective manner.

• It has a very high tensile strength - 8 times that of steel.

• It is highly absorbent when used as a basis for aerogels or foams.

• The raw material - cellulose - is the most abundant polymer on earth.

• Nanocellulose is biocompatible, meaning that it is not toxic to living tissue and can, therefore, be used in biomedical applications.

• Due to its plant-based origin, nanocellulose is also biodegradable.

How is Nanocellulose Produced?

Nanocellulose is generally produced from wood pulp though it can also be prepared from any cellulosic source material. Nanocellulose is produced using the following steps:

- Remove non-cellulose impurities from the wood pulp using a homogenizer. The high-pressure homogenizers used in the production process help delaminate the cell walls of the fibers and separate the nanosized fibrils.

- Separate the cellulose fibers by beating the mixture gently.

- Allow the fibers to form a thick paste of needle-like crystals or a spaghetti-like structure of cellulose fibrils.

- The thick paste that is obtained can be shaped and readily used to laminate surfaces.

Once it is completely separated from the wood pulp, nanocellulose is in a water suspension. At this stage, care should be taken to prevent the formation of rough clumps in cases when the cellulose fibers stick together as the material dries.

Researchers have thus developed a process that allows nanocellulose to dry without the formation of rough clumps. This process thus prevents the cellulose fibrils in nanocellulose from sticking together and enables the cellulose fibers to retain their mechanical properties.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/download-sample/5997

Nanocellulose Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 947.96 Million |

| Revenue forecast in 2035 | USD 6,447.32 Million |

| Growth Rate | CAGR of 23.74% from 2025 to 2035 |

| Base year for estimation | 2025 |

| Historical data | 2020 - 2025 |

| Forecast period | 2025 - 2035 |

| Segments covered | By Product Type, By Raw Material Source, By Processing Technology, By End-Use Industry, By Form, By Region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Country scope | U.S.; Canada; Mexico; U.K.; Germany; The Netherlands; Finland; France; Norway; Sweden; Switzerland; Spain; China; India; Japan; South Korea; Australia; Thailand; Malaysia; Singapore; Brazil; Colombia; Chile; Israel; Saudi Arabia; Iran; South Africa |

| Key companies profiled | Cellu Force; Fiber Lean; NIPPON PAPER INDUSTRIES CO.; LTD.; Kruger INC; Borregaard AS; CelluComp; Melodea Ltd; Blue Goose Refineries; GranBio Technologies; Stora Enso Biomaterials |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

AI Revolutionizes the Future of Nanocellulose

AI is transforming the nanocellulose industry by accelerating material discovery and optimizing production processes with data-driven insights. Advanced algorithms help manufacturers improve yield, reduce energy consumption, and stabilize quality in large-scale nanocellulose extraction. AI-powered simulations enable faster development of new composites, coatings, and packaging formulations customized for specific mechanical or barrier requirements.

In supply chains, AI enhances forecasting, sustainability tracking, and raw-material optimization, supporting more efficient operations. Overall, AI is pushing the industry toward smarter manufacturing, faster innovation cycles, and broader commercial adoption of nanocellulose materials.

Private Industry Investments in the Nanocellulose Industry:

- Nippon Paper Industries’ Nanocellulose Expansion – The company has invested in scaling cellulose nanofiber (CNF) production to meet rising demand for sustainable packaging and industrial additives.

- Stora Enso’s Bio-based Materials Funding – Stora Enso invested heavily in its pilot plant for microfibrillated cellulose (MFC) to accelerate the commercialization of bio-based packaging and coatings.

- Borregaard’s Speciality Cellulose Investments – Borregaard continues investing in advanced nanocellulose capacity to support high-performance applications in adhesives, composites, and personal care.

- CelluForce’s Nanocrystalline Cellulose (NCC) Projects – Private funding has strengthened CelluForce’s ability to expand NCC production for barrier films, rheology modifiers, and specialty materials.

- FiberLean Technologies’ Joint Venture Investments – The company has received private capital to scale MFC-based solutions for paper strength enhancement and filler substitution.

- UMV Coating Systems’ Nanocellulose Coating Developments – UMV has invested in nanocellulose-based coating technologies to improve sustainable packaging performance.

- GranBio’s R&D Funding for Bio-based Nanomaterials – GranBio has invested in nanocellulose innovations derived from agricultural residues to support greener industrial products.

- American Process Inc. (API) Nanocellulose Initiatives – API invested in developing cost-efficient nanocellulose extraction processes to make bio-based materials more commercially viable.

What are the Key Trends of the Nanocellulose Market?

- Rising demand for sustainable products: Growing environmental awareness and increasing regulatory pressure are driving demand for biodegradable, eco-friendly materials like nanocellulose as a replacement for petroleum-based products in various industries.

- Increased use in composites and coatings: Nanocellulose is being adopted as a lightweight, high-strength reinforcement material in composites for the automotive, construction, and electronics industries, as well as for improving the barrier properties and strength of coatings.

- Expansion of biomedical applications: The biocompatibility and unique properties of nanocellulose are leading to its increased use in the healthcare sector for advanced wound dressings, drug delivery systems, tissue engineering scaffolds, and medical devices.

- Advancements in production technologies: Ongoing research and innovation in manufacturing processes, such as enzymatic pretreatments and AI-optimized production, are reducing costs, improving scalability, and enabling the development of customized nanocellulose grades.

-

Growth in electronics and energy storage: Nanocellulose's excellent properties are making it an emerging material for use in flexible printed electronics, battery separators, and other energy storage applications.

Market Opportunity

Nanocellulose’s Breakthrough Potential in Sustainable Packaging

A major opportunity in the nanocellulose market lies in its expanding use as a sustainable alternative to plastic in high-barrier packaging applications. As global regulations push companies toward eco-friendly materials, nanocellulose offers excellent strength, biodegradability, and oxygen-barrier performance that can replace conventional petroleum-based films. Innovations in coating technologies and large-scale production are making it increasingly viable for food, cosmetics, and pharma packaging. This shift positions nanocellulose as a key material in the next generation of green, high-performance packaging solutions.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/download-sample/5997

Nanocellulose Market Segmentation Insights

Product Type Insights

In 2024, the cellulose nanofibrils (CNF) segment dominated the market because of its broad applicability across packaging, coatings, composites, and biomedical products. CNF offers excellent mechanical strength, flexibility, and rheology-modifying properties, making it highly versatile for industrial use. Its production processes are more mature and scalable compared to other nanocellulose types, enabling wider commercial availability.

The bacterial nanocellulose (BNC) segment is growing fastest over the forecast period due to its exceptional purity, biocompatibility, and unique 3D nanofiber structure, which make it ideal for medical and cosmetic applications. Its superior water-holding capacity and mechanical strength enabled advanced use in wound dressings, tissue engineering, and cell culture scaffolds. Growing interest in premium skincare and biomedical products further accelerated demand for BNC-based formulations.

Raw Material Source Insights

The wood-based pulp segment led the market in 2024 because it remains the most abundant, cost-efficient, and scalable raw material source for nanocellulose production. Established forestry industries and supply chains enabled consistent availability of high-quality pulp, reducing manufacturing costs and supporting large-scale commercialization. Its compatibility with existing mechanical and chemical production processes also made it easier for manufacturers to adopt without significant infrastructure changes.

The non-wood biomass segment is projected to grow fastest in the market, because industries increasingly sought low-cost, renewable feedstocks derived from agricultural residues, fibers, and food-processing waste. Its strong sustainability profile is aligned with global efforts to reduce reliance on wood-based resources and promote circular economy practices. Non-wood materials also offered diverse cellulose structures that supported high-performance nanocellulose production for packaging, composites, and biomedical applications.

Processing Technology Insights

The mechanical fibrillation segment dominated the market in 2024, because it is one of the most established and widely adopted methods for producing cellulose nanofibrils at scale. It offers a cleaner, chemical-free approach that aligns well with industry sustainability goals and regulatory expectations. Advancements in refining, homogenization, and energy-efficient processing technologies significantly reduced production costs, making it more commercially attractive.

The chemical & enzymatic pretreatment segment is growing fastest over the forecast period, because these processes significantly reduce the energy required for fibrillation, making production more cost-effective and scalable. Pretreatment improves fibre separation and uniformity, resulting in higher-quality nanocellulose with enhanced performance properties. This method also allows manufacturers to tailor nanocellulose characteristics for specialized applications in packaging, biomedical materials, and high-strength composites.

End-use Industry Insights

The packaging segment led the market in 2024, due to rising demand for sustainable, biodegradable materials that can replace traditional plastics. Nanocellulose offers excellent barrier properties, mechanical strength, and lightweight performance, making it highly suitable for food, cosmetic, and pharmaceutical packaging. Increasing regulatory pressure to reduce plastic waste and adopt eco-friendly alternatives further accelerated its adoption across major industries.

The healthcare & life sciences segment is the second-largest segment, leading the market, because of its growing use in advanced wound care, tissue engineering, and drug delivery systems. Nanocellulose’s biocompatibility, high absorbency, and customizable structure made it ideal for creating safe, effective biomedical materials. Rising demand for antibacterial, breathable, and flexible medical dressings further strengthened its adoption in clinical applications.

Form Insights

In 2024, the wet form (Suspension / Gel) segment dominated the market because it is the most commonly produced and commercially available form, simplifying handling and processing across industries. Its high dispersibility and stability in aqueous systems make it ideal for applications in packaging, coatings, biomedical products, and rheology modification. Manufacturers prefer the wet form because it avoids the high costs and energy demands associated with drying nanocellulose.

The dry form (Powder / Aerogel) segment is expected to grow fastest in the market because its lightweight, stable, and easily transportable nature made it highly attractive for global supply chains. Dry nanocellulose offers longer shelf life and lower storage costs compared to wet suspensions, supporting broader industrial adoption. Its compatibility with polymers, composites, and advanced materials positioned it as a preferred input for electronics, automotive, and high-performance packaging applications.

Regional Insights

Europe Leads the Charge in Nanocellulose Innovation

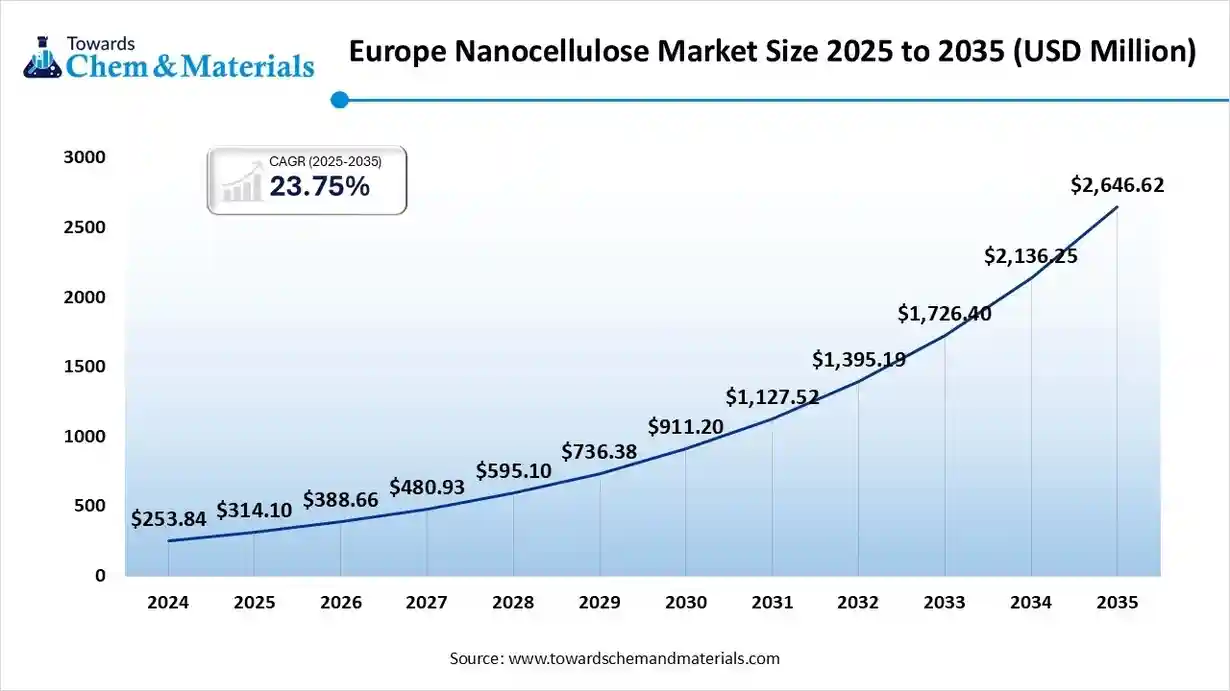

The Europe nanocellulose market size was valued at USD 314.10 billion in 2025 and is expected to reach USD 2,646.62 billion by 2035, growing at a CAGR of 23.75% from 2025 to 2035. Europe dominated the nanocellulose market with a 41% share in 2024.

Europe dominates the market due to its strong emphasis on sustainability, circular economy initiatives, and strict environmental regulations driving the adoption of bio-based materials. The region benefits from advanced research institutions and well-funded pilot plants that accelerate the commercialization of cellulose nanofibers and nanocrystals. Major European companies like Stora Enso, Borregaard, and UPM are actively investing in scaling production and developing high-performance applications across packaging, automotive, and coatings.

Additionally, collaborative EU programs and green funding initiatives continue to support technological advancements, reinforcing Europe’s leadership in the global nanocellulose landscape.

The UK Nanocellulose Market Trends

The UK market is gaining momentum as industries increasingly seek sustainable, high-performance materials for packaging, construction, and advanced manufacturing. Growing research investments from universities and private companies are accelerating innovation in nanocellulose-based composites, coatings, and barrier materials. Additionally, the country’s focus on reducing plastic waste and enhancing circular economy practices is encouraging broader adoption of bio-based nanocellulose solutions across multiple sectors.

Asia Pacific Emerges as the Next Nanocellulose Powerhouse

Asia Pacific is witnessing the fastest growth in the market, driven by expanding manufacturing industries and strong demand for sustainable materials. Rapid industrialisation in China, Japan, India, and South Korea is fueling the adoption of nanocellulose in packaging, electronics, and automotive applications. Governments across the region are also promoting bio-based materials and investing in R&D to reduce reliance on synthetic polymers. With rising environmental awareness and large-scale production capabilities, the Asia Pacific is quickly becoming a key growth engine for the global nanocellulose industry.

Japan Nanocellulose Market Trends

Japan’s market is growing steadily as the country expands its focus on advanced biomaterials for high-performance applications in electronics, automotive components, and packaging. Strong government support and collaborations between universities, chemical companies, and paper manufacturers are accelerating innovation in cellulose nanofibers (CNF) and nanocrystals (CNC). Additionally, Japan’s push for lightweight, sustainable, and high-strength materials is boosting commercialisation efforts and driving wider adoption across industrial sectors.

Top Companies in the Nanocellulose Market & Their Offerings:

- FiberLean Technologies Ltd.: Produces high-solids microfibrillated cellulose (MFC) for paper industry enhancement.

- American Process Inc.: Develops commercial technologies for cellulose nanofibers (CNF) and nanocrystals (CNC) for composites and paper.

- RISE Innventia AB: A research institute focused on R&D, piloting, and innovation in nanocellulose rather than mass commercial production.

- Kruger Inc.: Produces nanocellulose via a subsidiary for integration into lightweight automotive parts and packaging.

- GranBio Technologies: A Brazilian producer focusing on diverse uses including rubber reinforcement, food packaging barriers, and biomedical applications.

- Melodea Ltd.: Develops cellulose nanocrystals (CNC) specifically for sustainable barrier coatings in food packaging.

- Oji Holdings Corporation: A major manufacturer producing nanocellulose for integration into high-performance paper products and composites.

- Norske Skog ASA: A pulp and paper company diversifying into nanocellulose for various industrial applications beyond traditional paper.

-

CelluComp Ltd.: Produces "Curran" nanocellulose from sugar beet pulp, used as a rheology modifier in paints and composites.

More Insights in Towards Chemical and Materials:

- Automotive Paints & Coatings Market : The global automotive paints & coatings market size is calculated at USD 22.09 billion in 2025 and is predicted to increase from USD 23.88 billion in 2026 and is projected to reach around USD 48.22 billion by 2035, The market is expanding at a CAGR of 8.12% between 2026 and 2035.

- Green Hydrogen Market : The global green hydrogen market size is calculated at USD 12.85 billion in 2025 and is predicted to increase from USD 18.18 billion in 2026 and is projected to reach around USD 413.20 billion by 2035, The market is expanding at a CAGR of 41.49% between 2026 and 2035.

- Polylactic Acid Market : The global polylactic acid market size is calculated at USD 2.33 billion in 2025 and is predicted to increase from USD 2.74 billion in 2026 and is projected to reach around USD 11.74 billion by 2035, The market is expanding at a CAGR of 17.55% between 2026 and 2035.

- Mycelium-Based Building Materials Market : The global mycelium-based building materials market size is calculated at USD 1.21 billion in 2025 and is predicted to increase from USD 1.36 billion in 2026 and is projected to reach around USD 3.81 billion by 2035, The market is expanding at a CAGR of 12.15% between 2026 and 2035.

- Cork Building Materials Market : The global cork building materials market size is calculated at USD 8.84 billion in 2025 and is predicted to increase from USD 9.63 billion in 2026 and is projected to reach around USD 20.82 billion by 2035, The market is expanding at a CAGR of 8.95% between 2026 and 2035.

- Copper Products Market : The global copper products market size is calculated at USD 375.85 billion in 2025 and is predicted to increase from USD 397.09 billion in 2026 and is projected to reach around USD 651.19 billion by 2035, The market is expanding at a CAGR of 5.65% between 2026 and 2035.

- Aerospace Adhesives And Sealants Market : The global aerospace adhesives & sealants market size is calculated at USD 1.85 billion in 2025 and is predicted to increase from USD 1.98 billion in 2026 and is projected to reach around USD 3.66 billion by 2035, The market is expanding at a CAGR of 3.66 between 2026 and 2035.

- Ethanol 2.0 Market : The global ethanol 2.0 market size is calculated at USD 121.61 billion in 2025 and is predicted to increase from USD 130.35 billion in 2026 and is projected to reach around USD 243.50 billion by 2035, The market is expanding at a CAGR of 7.19% between 2026 and 2035.

- Sustainable Catalysts Market : The global sustainable catalysts market size is calculated at USD 5.85 billion in 2025 and is predicted to increase from USD 6.49 billion in 2026 and is projected to reach around USD 16.54 billion by 2035, The market is expanding at a CAGR of 10.95% between 2026 and 2035.

- Ethanol Market : The global ethanol market size is calculated at USD 114.98 billion in 2025 and is predicted to increase from USD 121.49 billion in 2026 and is projected to reach around USD 199.40 billion by 2035, The market is expanding at a CAGR of 5.66% between 2026 and 2035.

- Chemical Industry Market : The global chemical industry market size is calculated at USD 880.27 billion in 2025 and is predicted to increase from USD 922.96 billion in 2026 and is projected to reach around USD 1,413.51 billion by 2035, The market is expanding at a CAGR of 4.85% between 2026 and 2035.

- Aerospace and Defense Materials Market : The global aerospace and defense materials market size is calculated at USD 28.59 billion in 2025 and is predicted to increase from USD 30.18 billion in 2026 and is projected to reach around USD 49.07 billion by 2035, The market is expanding at a CAGR of 5.55% between 2026 and 2035.

-

Ethanol Market : The global ethanol market stands at 95.08 million tons in 2025 and is forecast to reach 142.24 million tons by 2035, expanding at a CAGR of 4.11% from 2026 to 2035.

Nanocellulose Market Top Key Companies:

- FiberLean Technologies Ltd.

- American Process Inc.

- RISE Innventia AB

- Kruger Inc.

- GranBio Technologies

- Melodea Ltd.

- Oji Holdings Corporation

- Norske Skog ASA

-

CelluComp Ltd.

Recent Breakthrough in the Nanocellulose Industry:

- In June 2025, Toyo Seikan Group Holdings, Ltd participated as nano Cellulose Japan in the Life Expo “Future Life Experience” at Expo 2025, Osaka, Kansai, Japan. During this period, NCJ exhibited the “New ECOCRSTAL Cup” that used Japan’s first cellulose nanocrystals (CNC).

Nanocellulose Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Nanocellulose Market

By Product Type

- Cellulose Nanofibrils (CNF)

- Cellulose Nanocrystals (CNC)

- Bacterial Nanocellulose (BNC)

By Raw Material Source

- Wood-Based Pulp

- Non-Wood Biomass

- Microbial / Bacterial Sources

By Processing Technology

- Mechanical Fibrillation

- Chemical & Enzymatic Pretreatment

- Electrospinning & Freeze-Drying

By End-Use Industry

- Packaging

- Automotive & Aerospace

- Healthcare & Life Sciences

- Textiles & Personal Care

- Construction & Coatings

By Form

- Dry Form (Powder / Aerogel)

- Wet Form (Suspension / Gel)

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/download-sample/5997

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.